Cost price determines the establishment’s survival. Restaurateurs often set prices intuitively, based on competitors. Six months later they discover losses with a full dining room.

Cost calculation shows the real picture. Without accurate data for each item, it’s impossible to understand which dishes bring profit and which eat away margins. Restaurant management accounting helps see menu profitability in real time and adjust pricing based on facts, not assumptions.

Formula for Calculating Dish Cost

The formula is based on summing the costs of all components. The cost of each ingredient is multiplied by its quantity in a portion, then all components are added together.

Basic formula: dish cost = sum (ingredient cost × quantity in grams) + processing losses. Cost calculation requires knowledge of purchasing prices from suppliers and product weight for preparation.

Calculating costs for each ingredient accounts for not only main products. Spices, cooking oil, salt — all this affects the final amount. A salad may seem cheap until you calculate the cost of ten types of greens and dressing.

The weight of a dish on a plate doesn’t equal the weight of products at purchase. Meat loses up to 30% of mass during heat treatment, vegetables during cleaning — 15-25%. Potatoes weighing 100 grams raw will yield 70-75 grams of cooked side dish.

What Affects Cost in the Restaurant Business

Food cost — the percentage of cost price from the selling price of a dish. The standard for food service is 25-35%. Above 40% — the establishment operates at a loss, below 20% — prices are inflated and scare away guests.

Preparation costs include not only products. Chef and kitchen staff salaries are distributed proportionally to production volume. Utilities, equipment depreciation — all this indirectly affects the final dish cost.

Portion sizes are critical for cost control. A chef adds pasta “by eye” — the portion can differ by 20-30% from the standard. Overspending 50 grams of spaghetti per order with 100 portions a day eats up a significant part of earnings.

Waste write-offs must be included in dish cost calculation. Fish when butchered loses head, fins, bones — up to 40% of weight. Don’t account for losses — you’ll get a gap between theoretical and actual cost.

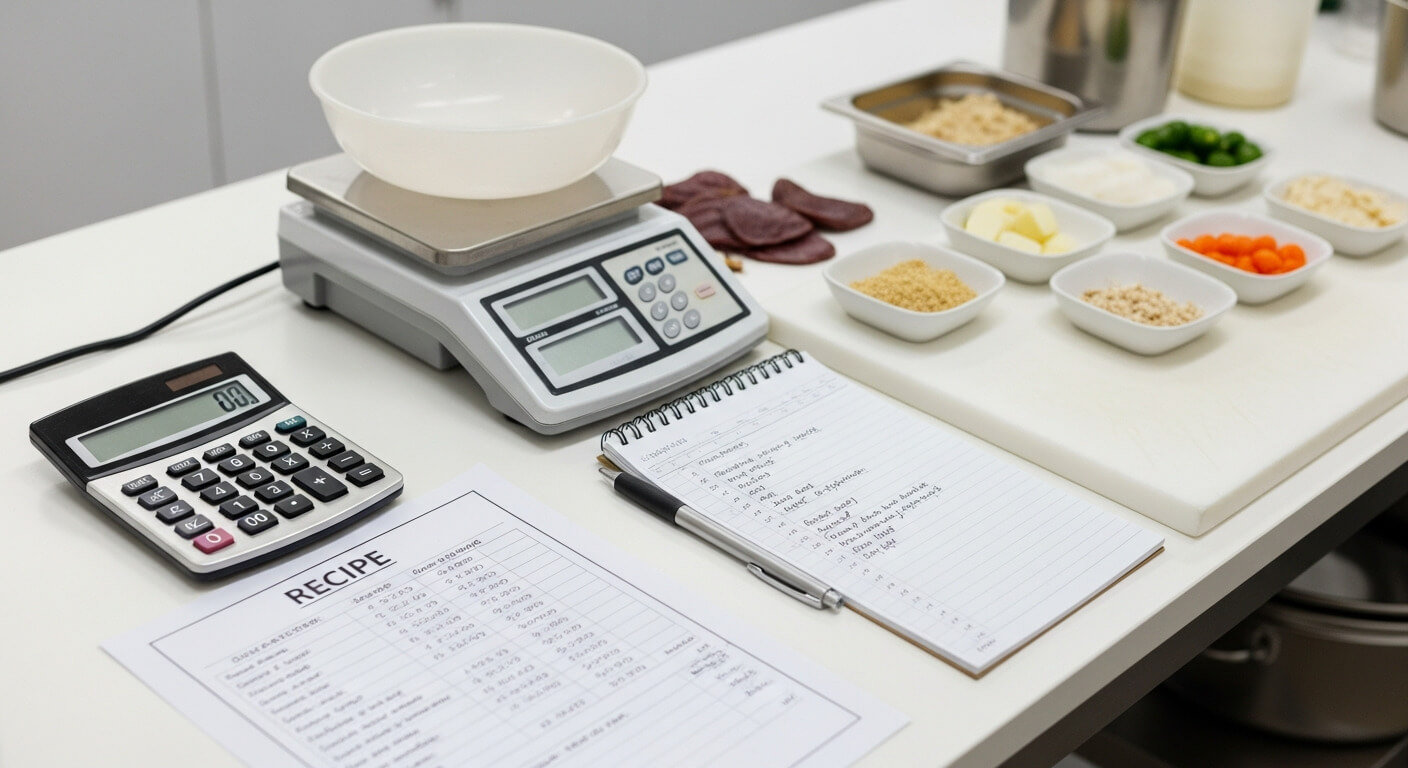

Recipe Cards and Menu Standardization

Recipe cards record the exact recipe for each dish. Weight of each ingredient, sequence of dish preparation, temperature, cooking time. Without a standard, one chef cooks tasty and expensive, another — economical but not tasty.

Composing recipe cards requires weighing all components. Beverage, sauce, side dish — each item has its own calculation. Complex restaurant dishes consist of several semi-finished products, each with its own cost.

Restaurant software automates work with recipe cards. The program recalculates cost when purchasing prices from suppliers change. A product became 15% more expensive — the system instantly shows the new calculation for all dishes where it’s used.

Tracking actual consumption by recipe cards reveals deviations. If theoretically 50 portions of borscht need 10 kg of beets, but you have to write off 12 kg — the problem is in preparation or theft.

Methods of Reducing Food Cost Without Quality Loss

The goal of food cost is to keep the indicator within 28-32% for full-cycle restaurants. Food cost reduction is achieved in several ways without harm to the guest.

Reviewing the menu for low-margin items. If a dish gives a food cost of 45% and sells rarely — it makes sense to remove it. Or revise the recipe, replacing expensive ingredients with affordable alternatives.

Portion control reduces overspending. Scales in the kitchen, measuring spoons, portioning scoops — tools for standardization.

Working with suppliers at low prices while maintaining quality. Direct purchases from manufacturers instead of intermediaries provide 10-20% savings. But require large volumes and stability.

Accounting automation allows tracking actual consumption in real time. Calculating deviations manually for 200 menu items is physically impossible. The program does this automatically and shows problem areas.

Automation of Cost Calculation and Control

Properly built cost accounting is impossible without software solutions. Syrve for restaurant calculates cost automatically with each sale.

The accountant sees only final figures after the fact. Management needs data here and now. How much profit the restaurant made yesterday, which dishes lead in profitability, where there’s ingredient overspending.

The system writes off products by recipe cards automatically. The waiter processes a check — the program subtracts the exact quantity of all components from inventory. Revenue grows, and warehouse inventory drops proportionally.

Calculating the cost of a dish manually for a menu of 150 items is a week-long task. The program does this in seconds and updates data with each change in purchasing prices.

Restasystem works with establishments of any format. You can account for both dishes and beverages, semi-finished products, component ingredients. Time spent on implementation pays off through food cost control and profit.

Cost Control as the Basis of Profitability

Calculating cost once is not enough. Supplier prices change, seasonality affects product availability, pricing requires constant adjustment.

Food cost control is the basis of profitability in the restaurant business. An establishment with full seating can lose money due to incorrect calculation. Cost calculation and consumption monitoring provide understanding of the real picture.

Modern management accounting tools allow optimizing processes without hiring additional staff. Accurate data for each dish helps make informed decisions about menu, markup, and purchases.